How A Plastic Injection Manufacturer Reduced Energy Costs By 32.6% with Onics

Problem

A plastic injection manufacturer was facing reduced equipment reliability and increased energy costs caused by increased harmonic distortion in its electrical system.

Due to load configurations and stop-and-go, small batch manufacturing runs, the facility suffered from pronounced levels of harmonics leading to lower power quality, higher peak currents, and significant energy waste.

In addition, the heat caused by harmonic distortion negatively impacted the performance and life expectancy of critical manufacturing equipment and led to frequent lighting replacement.

Solution

The manufacturer worked with Onics Energy Solutions to mitigate the harmful effects of harmonics with the Onics OES-11 Passive Neutral and Ground Harmonic Filter. Onics first installed a revenue-grade metering solution to establish a baseline on energy consumption measured in kWh. The Onics team then installed OES-11 passive harmonic filters on every electrical sub panel in the facility.

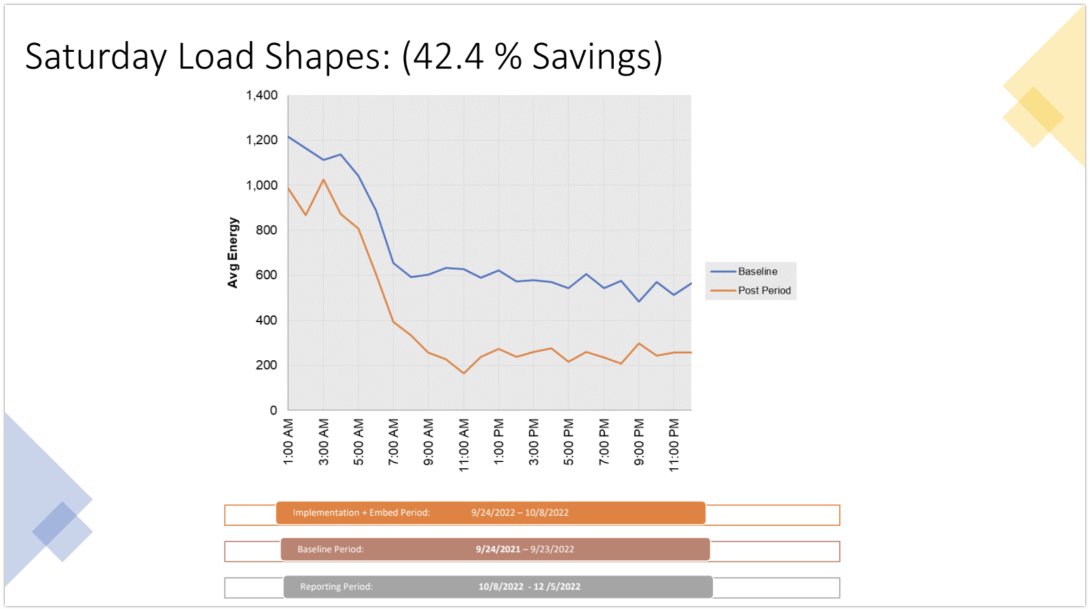

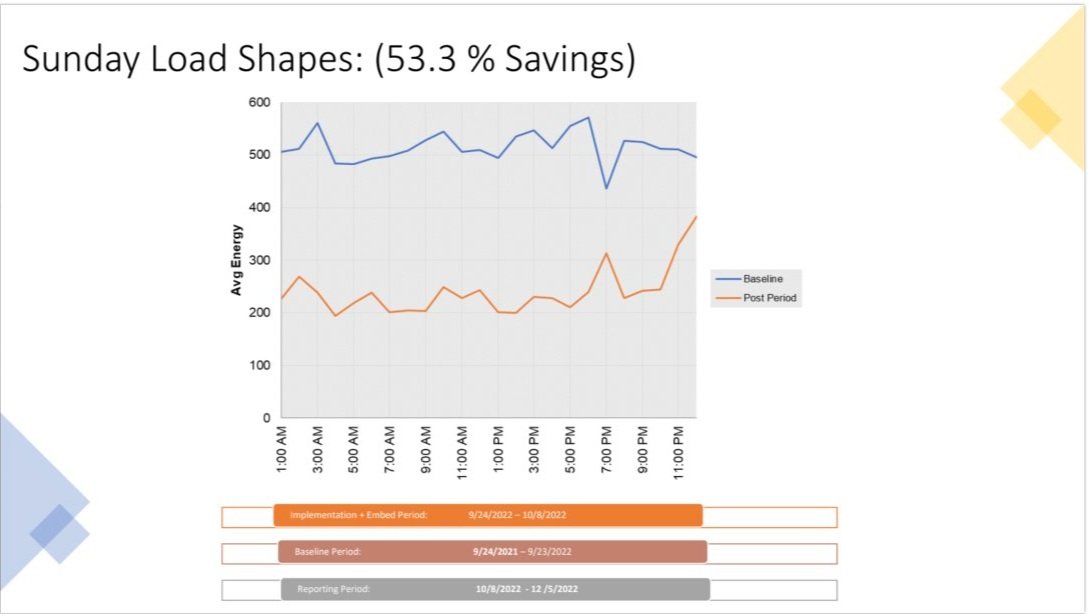

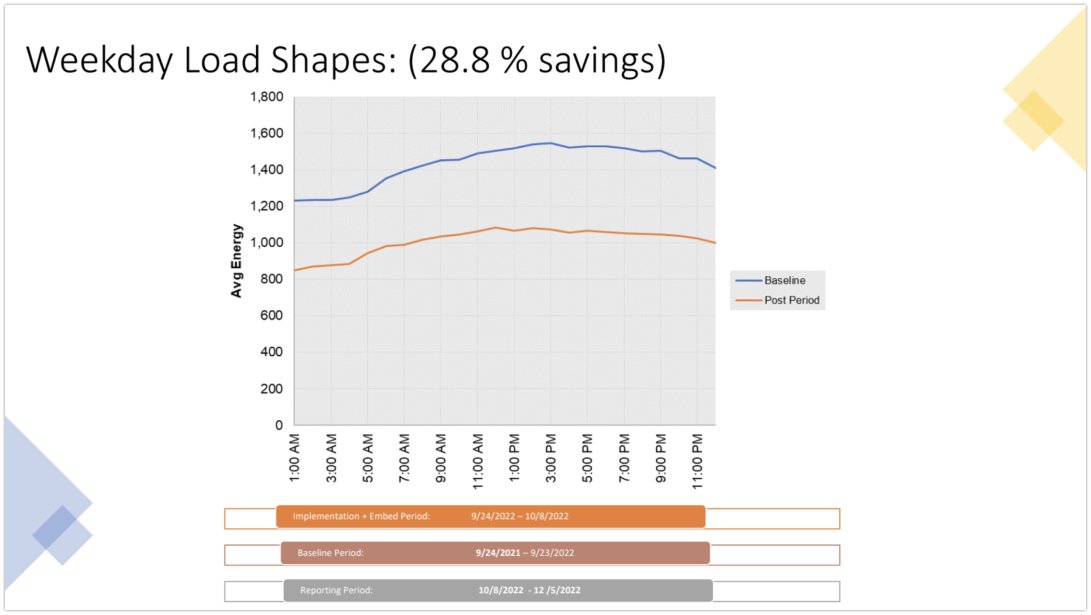

After a reporting period of 58 days, a licensed, 3rd party Measurement and Verification (M&V) Energy Expert analyzed power consumption data and production KPIs to calculate the energy savings resulting from the installation of Onics OES-11 Passive Harmonic Filters.

Result

The 3rd party M&V Energy Expert directly tied an overall reduction of 32.6% kWh to the installation of the Onics OES-11 Passive Neutral and Ground Harmonic Filters.